Reviews and reports

Sustainability report

This report provides a summary of health, safety, environmental and sustainable development performance across the operations of the Assore group. Assore also recognises that it has a responsibility to promote the sustainability of its business by taking an active role in shaping the development and performance of its business in the sectors in which it operates.

- Assmang, jointly controlled by Assore 50% and African

Rainbow Minerals Limited (ARM) 50%, which includes the

following operations:

- Khumani Iron Ore Mine (Khumani);

- Beeshoek Iron Ore Mine (Beeshoek);

- Black Rock Manganese Mines (Black Rock);

- Cato Ridge Works ferromanganese smelter, incorporating Cato Ridge Alloys (CRA) (Cato Ridge Works);

- Dwarsrivier Chrome Mine (Dwarsrivier); and

- Machadodorp Works ferrochrome and ferromanganese smelter (Machadodorp Works)

- AMT operations, being the subsidiary companies of Assore, which include:

- Rustenburg Minerals Development Company (Proprietary) Limited (RMDC);

- Zeerust Chrome Mines Limited (Zeerust);

- Wonderstone Limited (Wonderstone); and

- Head Office operations (Head Office), combining African Mining and Trust Company Limited (AMT) and Ore & Metal Company Limited (Ore & Metal).

In previous years, this report has reported on the sustainability performance of the Xertech operation. However, Xertech ceased production in early 2010, and is therefore not included in the data sets presented in this section.

The group recognises that sustainable development issues are material to its business beyond the level of legal compliance in response to customer requirements, regulator and stakeholder expectations and continues to focus on strengthening its internal capacity, management systems and stakeholder engagement as part of corporate strategy.

Management systems

The group’s sustainability risk management systems are based on the International Standards Organisation (ISO) suite of standards.

All group operations are certified to the ISO9001:2008 quality and the ISO14001:2004 environmental standards (with the exception of Zeerust, which will seek certification in the forthcoming financial year). In the year under review, RMDC was certified to ISO14001 in October 2010, and Khumani was certified to ISO9001 in November 2010 and ISO14001 in January 2011.

Certification to the internationally recognised OHSAS18001 occupational health and safety management standard has been achieved at all Assmang operations with the exception of Black Rock, which will seek certification in the coming year. Khumani is the most recent of the operations to be certified to OHSAS18001, which was achieved in January 2011.

Approach to reporting

Over the past year, data gathering and reporting systems have continued to evolve to provide management with timely information to inform their decisions and actions. Report formats have expanded to report on a wider range of sustainability indicators that allows health, safety and sustainability considerations to be incorporated into decision making on a systemic and ongoing basis.

Environment, health and safety staff on the sites report directly to mine management and are also supported by corporate staff who are responsible for establishing group-wide policy and performance standards, facilitating internal and external reporting [8 and auditing operational performance. Material issues such as fatalities, lost time injuries (LTIs), major environmental incidents and issues of legal non-compliance are reported to Assore’s group Technical Director as soon as they occur. Quarterly reports on compliance with safety, health and environmental legislation for all group operations are submitted to the Assore Audit and Risk committee for review. Similarly, a review of safety, health and environmental performance takes place quarterly within Assmang and is attended by divisional executives and corporate personnel as well as senior operational staff.

The group reports on sustainability performance in accordance with Global Reporting Initiative (GRI) G3 indicators. A suite of reporting indicators has been selected on the basis of their materiality to the specific risk profile of the operations and are referred to in the sections below. More detail on the assurance of the sustainability data sets is included here.

Legal compliance

Legal compliance is the foundation of the group’s environmental, health and safety policies and is the basis on which the group’s environmental, health and safety management systems have been developed. Legal compliance is a minimum performance requirement for the group’s operations and is determined by a programme of ongoing internal and external reviews and audits against the requirements of the relevant legislation.

As part of their ISO-based management systems, each operation has a site-specific legal register detailing the applicable legislation with which the operation needs to comply. Legal audits for both Assmang and the AMT operations are performed on a biannual basis to confirm that all sites have either been granted, or have at least applied for by the group, all permits, licences, authorisations and exemptions required to operate in compliance with the requirements of the health, safety and environmental law. However, due to limitations in the respective regulators’ capacity, significant delays are still being experienced in the issuing of environmental permits, licences and authorisations, as well as the approval of EMP amendments. Nonetheless all sites continue to ensure that all reasonable steps are taken to achieve legal compliance as a minimum.

Compliance with environmental legislation

All mining operations within the group have approved EMPRs, as required in terms of the MPRDA. In order to reflect the dynamic nature of the operations and changes to mining operations and infrastructure, these documents undergo periodic review and revision and are resubmitted to the Department of Mineral Resources (DMR) for authorisation.

During the period under review, an amendment to the Wonderstone EMP was approved, and the Zeerust EMP was revised and upgraded to include infrastructure associated with open-cast mining, plant upgrade and expansion of the tailings facilities.

In the 2011 financial year, the necessary environmental authorisations were also secured to permit the conversion of two ferrochrome smelters at the Machadodorp Works to ferromanganese production which commenced during the year. No fines or prosecutions were incurred by either Assmang or the AMT operations over the current financial year.

No fines or prosecutions were incurred by either Assmang or the AMT operations over the current financial year.

Compliance with health and safety legislation

During the year, a total of three Section 54 notices were issued

to Assmang operations in terms of the MPRDA, resulting in a total loss of five days production at Dwarsrivier and one day

of production at Black Rock. This compares favourably with

the seventeen Section 54 notices issued during the preceding

year. One Section 54 notice was issued to Zeerust during the

current financial year, resulting in a five day production loss, as

compared to no Section 54 notices served to the AMT operations

in the previous financial year.

No prohibition notices in terms of the Occupational Health and Safety Act (OHSA) were served at either of the two smelter operations by the Department of Labour during the financial year.

Climate change and energy consumption

In response to growing consumer concern about climate change and pending national climate change legislation, the group has embarked on a process of understanding and responding to the risk that climate change poses to its business.

As an intensive energy user, energy consumption, and the resultant greenhouse gas emissions which are linked to climate change, is a material environmental issue for the group. Reduction in gaseous emissions is also linked to legal compliance with respect to emission licences issued in terms of the National Environmental Management: Air Quality Act and also has potential implications for the proposed taxation of carbon emissions.

Climate change poses a potential threat to water availability as most operations are located within the arid zone, and also has implications in terms of compliance with other environmental legislation, such as the National Water Act.

For most sites, diesel consumption in the reporting year has been broadly in line with consumption during previous years except for Khumani which reflected a 55% increase in diesel consumed resulting from the mining and construction activities associated with the Khumani Expansion Project (KEP).

For the AMT operations, diesel consumption at Zeerust has increased significantly as a result of the ramp-up of the open-cast operations.

In terms of electricity consumption, the most material change has been a 56% increase in electricity consumption at the Machadodorp smelter. This reflects increased smelter operation during the reporting year, after a decline in production in 2010, during which the furnaces were switched out for an extended period.

| Electricity and diesel consumption | ||||||

| Diesel | Diesel | Electricity | Electricity | |||

|---|---|---|---|---|---|---|

| use | use | use | use | |||

| 2011 | 2010 | 2011 | 2010 | |||

| Operation | 000ℓ | ‘000ℓ | MWh | MWh | ||

| Beeshoek | 2 048 | 1 604 | 31 193 | 33 529 | ||

| Khumani | 27 535 | 18 844 | 101 078 | 87 720 | ||

| Black Rock | 4 119 | 3 094 | 101 078 | 87 609 | ||

| Cato Ridge Works | 524 | 642* | 588 410 | 533 183 | ||

| Dwarsrivier | 1 429 | 1 183 | 588 410 | 26 750 | ||

| Machadodorp Works | 1 501 | 417 | 1 007 538 | 645 107 | ||

| RMDC | 2 642 | 2 730* | 4 092 | 4 123* | ||

| Zeerust | 1 993 | 104* | 1 285 | 200* | ||

| Wonderstone | 212 | 182* | 1 285 | 1 184* | ||

|

||||||

Greenhouse gas emissions and corporate carbon footprints

During the previous financial year, corporate carbon footprints (CCFs) were calculated for both Assmang and the AMT operations for the first time. This established a baseline for the measurement of the group’s energy consumption and greenhouse gas (GHG) emissions, and as a result of this exercise, routine reporting on energy consumption was modified to include parameters used to calculate the respective CCFs.

Methodology

The CCF for both Assmang and Assore has been calculated by

an external service provider, PE International, in accordance with

the Greenhouse Gas Protocol – Corporate Standard. The data

collation process complies with the data quality requirements set

out in ISO14044 as well as the GRI-G3 guidelines established by

the Global Reporting Initiative (GRI).

The carbon footprint has been calculated for sites, subsidiaries, operations and activities over which the group has operational control. Thus, GHG generation by activities associated with the group, but over which the group has no operational control, is not taken into account.

GHG emissions are split into three categories:

- Scope 1: Direct GHG emissions which occur from sources that are owned or controlled by the company (eg emissions resulting from diesel consumption by mine vehicle fleets, consumption of reductants in furnaces and burning of liquid petroleum gas)

- Scope 2: GHG emissions from the generation of purchased electricity consumed by the company. This is purchased from Eskom, whose power generation is predominantly sourced from the burning of coal

- Scope 3: GHG emissions which are a consequence of the company’s activity but occur from sources not owned or controlled by the company (eg business trave).

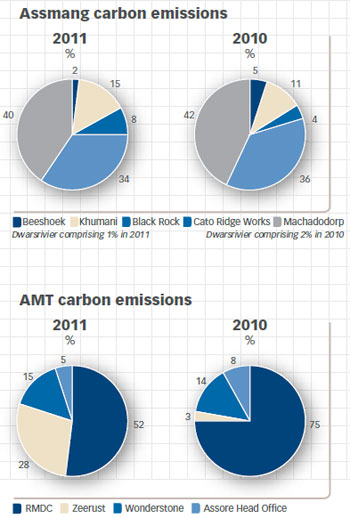

Summary of findings

The comparative data for the CCFs calculated for the previous

and current reporting period are presented in the figures below:

| Scope 1 | Scope 2 | Scope 3 | Total | |

|---|---|---|---|---|

| tons | tons | tons | tons | |

| 2011 | CO2e | CO2e | CO2e | CO2e |

| AMT operations | 12 891 | 8 174 | 1 156 | 22 221 |

| Assmang | 573 055 | 1 426 879 | 415 954 | 2 420 888 |

| 2010 | ||||

| AMT operations | 8 272 | 7 447 | 965 | 16 684 |

| Assmang | 584 717 | 1 277 003 | 257 223 | 2 118 943 |

The CCF demonstrated that Scope 2 emissions due to electricity consumption account for the bulk of Assmang’s GHG emissions, due to the energy intensive nature of smelting processes. By contrast, Scope 1 emissions predominate on both the Assmang and AMT operations, due to diesel consumption by the mine vehicle fleet.

Scope 3 emissions are dominated by rail transportation of bulk commodities for export from mine to port and are particularly significant for the Khumani and Black Rock operations.

Strategies to combat climate change

Over the reporting year, the group has focused on developing an integrated approach to mitigate the potential impacts of climate change on its operations.

Advocacy on issues related to climate change is undertaken through membership of the Intensive Energy Users’ Group and the Chamber of Mines who engage on an ongoing basis with Eskom and Government, and through the International Council on Metals and Mining (ICMM) which undertakes lobbying in this regard. Through these mechanisms, the group is engaging with Government on various aspects of the proposed taxation of carbon emissions, whose impact could be material to the group.

During the past financial year, Assmang introduced an Energy Efficiency Charter and is in the process of developing an energy reduction strategy and associated targets. Particular focus has been placed on improving the energy efficiency of the smelters at the Cato Ridge Works and Machadodorp Works (which are the group’s largest energy consumers). In order to incentivise the production teams to identify and implement reduction strategies for energy consumption, targets have been established for energy efficiency and progress against these targets has been integrated into staff performance assessment and bonus incentives at the smelters

Water

Virtually all of the group’s lines are located in water scare regions, and so priority is placed on water efficiency and the prevention of pollution that could compromise the suitability of the water resource for current and future water uses. Water consumption is reported on monthly, and monitoring of water levels and water quality is undertaken in accordance with corporate standards to demonstrate compliance with the site’s Water Use Licence.

| Water consumption | ||

| 2011 | 2010 | |

|---|---|---|

| Operation | m3 | m3 |

| Beeshoek | 4 611 620 | 5 426 839 |

| Khumani | 2 611 648 | 2 448 975 |

| Black Rock | 857 030 | 883 707 |

| Cato Ridge Works | 374 163 | 329 713 |

| Dwarsrivier | 362 522 | 73 638 |

| Machadodorp Works | 130 620 | 52 031 |

| RMDC | 286 202 | 173 485 |

| Zeerust | 22 255 | Monitoring |

| commenced | ||

| mid year | ||

| Wonderstone | 3 252 | 4 378 |

| * Includes water supply to the mine village. | ||

The most significant year-on-year increase in the volume of water consumption took place at Dwarsrivier, which increased by 101% compared to the previous year. This is due to the opening of the North shaft during the current year, which required significant additional pumping to dewater the workings.

In accordance with the group’s holistic approach to managing the potential impacts of climate change, the possible effects of climate change on water availability and storm magnitude are being considered.

During the past financial year, the Cato Ridge Works has undertaken a major programme of capital works to construct a series of three retention dams and one water storage dam to optimise the re-use of process water and prevent the release of contaminated water from site. This project will be commissioned by the start of the forthcoming rainy season and will minimise the risk of contaminated water being released from the site, as well as reducing consumption of make-up water as a result of greater water recycling and reuse. Beyond this, the sites continue to investigate opportunities for water use reduction, reuse and recycling on an ongoing basis.

Waste

Mining and smelting operations produce a range of waste streams that require specialist management and disposal and financial provision for the rehabilitation of waste facilities constitutes the majority of the group’s closure liability. In terms of volume, the most significant waste streams are tailings and waste rock generated by the mining operations, and slag from the smelters, as summarised in the table below.

In line with the principles of waste management outlined in the National Environmental Management: Waste Act, the operations are encouraged to actively pursue opportunities for waste recycling and reuse. At Cato Ridge, between October 2007 and June 2011, a total of 2 451 622 tons of slag produced by the Works has been processed through the Metal Recovery Plant, resulting in the recovery of a total of 109 200 additional tons of ferromanganese. Over the same period, 1 117 674 tons of slag (which would otherwise have been disposed of as waste on the slag dump) was sold into the concrete making industry. When offset against the 528 517 tons of new slag arising from production over the same period, the operation has therefore managed to reduce the size of the slag dump over the four-year period under consideration by 698 357 tons of slag.

In the current year, a number of the group mines have reprocessed historical mine waste deposits in order to generate product, thus reducing the volume of mine waste disposed of on site. Dwarsrivier has commenced with retreatment of tailings from the old tailings dam, which will allow the recovery of additional chrome, as well as the future extraction of Platinum Group Metals (PGMs). Similarly, historic tailings have been reprocessed at Zeerust in order to recover chrome and tailings from RMDC have been sold to third parties for chrome recovery.

| Waste generated by operations | ||||

| Waste rock/slag | Waste rock/slag | Tailings/slag | Tailings/slag | |

|---|---|---|---|---|

| 2011 | 2010 | 2011 | 2010 | |

| Operation | m3 | m3 | tons | tons |

| Beeshoek | – | – | 1 025 030 | 1 120 340 |

| Khumani | 11 776 314 | 15 423 509 | 1 262 318 | 1 310 810 |

| Black Rock | 97 265 | 135 541 | 158 550 | 352 376 |

| Cato Ridge Works | n/a | n/a | 163 483 | 252 227 |

| Dwarsrivier | 348 893 | 587 733 | 369 483 | 134 945 |

| Machadodorp Works | n/a | n/a | 539 185 | 78 304 |

| RMDC | 1 587 966 | 1 381 860 | 36 005 | 57 853 |

| Zeerust | 1 559 978 | n/a | 50 371 | 41 177 |

| Wonderstone | 149 470 | 130 529 | n/a | n/a |

| n/a = not applicable | ||||

Land management and mine closure

Land management is a material issue for the group since mining and minerals processing are temporary land uses and, on

closure, disturbed land must be rehabilitated to a state which

is safe, stable and does not pose a threat to the ecosystem and

human health. The land must thus be managed throughout the

life of the operation in a manner that is consistent with the end

land use(s) that have been agreed with key stakeholders, as outlined in the closure plans and provided for in the financial

closure provision.

Land management

In response to the requirement of the National Environmental

Management: Biodiversity Act, sites are required to develop

Biodiversity Action Plans (BAPs) to appropriately manage the on-site ecosystems. BAPS focus on identifying and implementing

responsible land management practices including the protection

of vulnerable ecosystems, the control and eradication of alien and

invasive species and veld fire management. These plans are also

used to influence decisions on site rehabilitation and revegetation

in order to identify sustainable post-closure land uses and select

rehabilitation techniques and species that are compatible with the

natural environment.

BAPs have been developed for all the AMT operations and have been integrated into the site’s environmental management systems.

All Assmang sites have commenced with biodiversity studies, and the biodiversity assessments have already been completed for the Dwarsrivier and Machadodorp operations. The Dwarsrivier and Machadodorp operations are of particular biodiversity significance as they are located within the Sekhukhune and Machadodorp centres of endemism. This means that they contain endemic species of flora which are not found elsewhere and management plans need to be developed and implemented to ensure that these species are not adversely impacted as a result of mining or smelting operations.

The construction of a new access road for the Cato Ridge Works will result in the fragmentation of 20 hectares of Ngongoni grassland, which has a high conservation status. A biodiversity offset agreement was confirmed in July 2010 between the Cato Ridge Works and various municipal and provincial government departments and is being presently implemented.

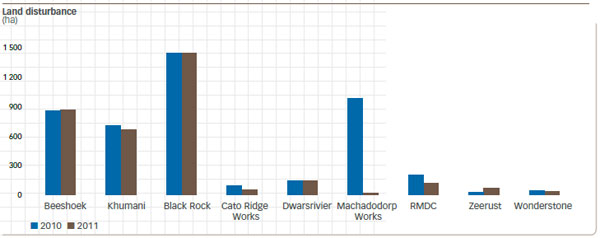

The graph below shows the areas of disturbed land at each operation as of the end of the reporting year.

The most significant percentage increase in disturbed land footprint took place at Zeerust as a result of the ramping up of open-cast mining operations. In the case of RMDC, a virtual halving of the disturbed land footprint reflects the shift from surface to underground mining production and the resultant rehabilitation of worked-out quarries. At Wonderstone, the disturbed footprint has also been significantly reduced as a result of concurrent rehabilitation.

Mine closure and financial provisions

Financial provision for mine closure and rehabilitation constitutes

the single largest environmental liability for the group’s mines,

constituting a total liability of R376 million (2010: R310 million) for Assmang and R17 million (2010: R17 million) for AMT operations.

Closure plans developed for the group mines inform the financial provision made for rehabilitation and closure, which is funded through a combination of contributions to environmental trust funds and bankers’ guarantees.

The largest change has been the closure provision for Khumani, which has increased by 120% year-on-year, reflecting the significantly increased footprint of disturbed land and associated mining infrastructure as a result of the KEP. The closure provision for Dwarsrivier has also increased by 32% year-on-year, as a result of two EIA processes for additional mining-related infrastructure, combined with an external review of the mine’s closure provision.

These closure provisions are reviewed and, where needs be, revised on an annual basis. Where possible, concurrent rehabilitation is undertaken in areas where mining and minerals processing has been completed. This allows the operations to test rehabilitation and revegetation techniques, the long-term sustainability of which can then be monitored, and also allows the operations to keep their ‘footprint’ of disturbed land (and the associated financial provision for closure) to a minimum.

All group mines have a conceptual closure plan which is a requirement of EMPR approval. As a minimum requirement, the MPRDA requires that mines that have a remaining life of five years or less are required to deliver a detailed closure plan. Although all of the group’s mines have mine lives considerably in excess of this, emphasis is being placed on the development of more detailed closure plans well ahead of mine closure to assist in rehabilitation planning and realistic financial provision for closure. As part of the Zeerust EMP amendment, the group undertook a focused programme of engagement with landowners, regulators and other interested and affected parties in order to develop a suite of quantifiable mine closure criteria that address the priorities of all stakeholders, and will allow the site to monitor and report on progress on concurrent rehabilitation in a meaningful manner and will provide a template for closure plans for all the AMT operations, which are scheduled for revision in the coming financial year.

The Cato Ridge Works and Machadodorp Works are classified as industrial (rather than mining) facilities and therefore there is no legal requirement to make financial provision for closure or rehabilitation of these operations. However, site remediation and rehabilitation at the group smelters is managed and provided for in accordance with the principles of responsible environmental management outlined in national legislation.

Human resources

The group undertakes statutory reporting on employment equity and other labour-related issues to both the Department of Labour and the DMR. The occupational levels and employment equity categories reported on are based on the definitions outlined in the Employment Equity Act and the Broad-based Socio-Economic Empowerment Charter for the Mining Industry (the Mining Charter) and are summarised below.

While the employment equity targets set in the Mining Charter do not apply to the group’s smelters, employment equity statistics are presented for the Cato Ridge works and the Machadodorp Works operations for the sake of complete and consistent reporting.

No staff were retrenched by either Assmang or Assore during the current financial year.

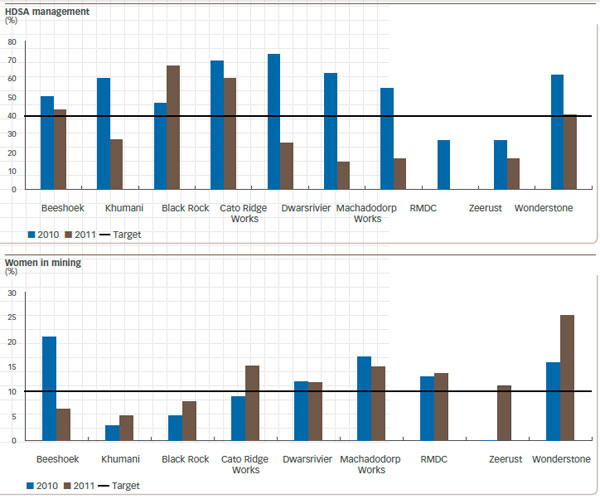

In line with the requirements of the Mining Charter, all of the group’s operations (with the exception of Black Rock) recorded a significant year-on-year increase in the proportion of Historically Disadvantaged South Africans (HDSAs) in management positions. All operations (with the exception of Zeerust) have exceeded the Mining Charter target of 40% HDSAs in management.

Although some operations reflected an improvement in the proportion of Women In Mining during the current year, compliance with the Mining Charter target of 10% for this indicator is proving to be challenging.

Although the proportion of Women In Mining appears to have decreased year-on-year for the majority of the group’s operations, this in fact is largely due to the adoption of a stricter definition of “women in mining” by Assmang during the current year. Assmang’s reporting convention on this indicator is now consistent with the criteria used by AMT operations with the statistics now reflecting the number of women in “core” production-related departments and excluding women in support departments (who were previously included in this category). Thus the year-on-year data sets for Assmang operations are not comparable.

The majority of the Assmang operations reported an increase in permanent staff complement during the current year, with the increase in permanent staff being particularly marked at Khumani and Black Rock.

The proportion of contractors on the Assmang sites has also increased year-on-year, and reflects the contractor workforce that has established to undertake major capital projects. This includes the KEP at Khumani, as well as the rebuild of furnaces 1 and 2 and a range of environmental improvement projects undertaken at the Cato Ridge Works.

Labour relations

Over the period between December 2010 and January 2011,

Dwarsrivier experienced an unprotected strike which lasted

for 13 days and affected three shifts. However, no strikes or

lockouts exceeding a week were experienced at any of the

AMT operations during the reporting year.

Safety

One of the group’s core values is ensuring that operations are managed in a manner that safeguards the safety and health of our employees.

To this end, existing management systems are continuously evolving to address the changing risk profile of our operations and we consistently strive to improve our safety performance so that workplace injuries and occupational diseases are minimised.

Once again, there were no fatalities at any of the AMT operations during the 2011 financial year. There was a single fatality at the Assmang operations during the year, when Mr Solomon Vusi Sindane a trainee crane operator, was fatally injured at the Machadodorp Works.

Lost time injuries (LTI) statistics and lost time injury frequency rates (LTIFR) for each of the operations are presented in the table above. The LTIFR is calculated on the basis of 200 000 hours.

During the 2011 financial year, both Khumani and Black Rock achieved one million fatality-free shifts.

Beeshoek recorded zero lost time injuries for twelve consecutive months. As at 30 June 2011, the mine had also recorded 1,9 million fatality-free shifts with the last fatality occurred during March 2003.

Health and wellbeing

The group recognises that proactively managing the health of the workforce is central to ensuring the sustainability of its business. In order to ensure that the specific occupational health risks associated with each of the operations are effectively managed, specialist occupational health service providers are engaged by each of the operations to implement medical surveillance programmes in accordance with legal requirements.

Occupational health and hygiene monitoring

The number of employees who underwent occupational health

screening (including the number of cases referred for follow up

and compensation) during the current year is summarised below:

| Occupational health screening | ||||||

| 2011 | 2010 | |||||

|---|---|---|---|---|---|---|

| Number | Number | |||||

| Number of | Number | of cases | Number of | of cases | Number | |

| audiometric | of cases | referred for | audiometric | referred for | of cases | |

| surveillance | submitted | audiometric | surveillance | audiometric | submitted | |

| tests | for | diagnostic | tests | diagnostic | for | |

| compen- | compen- | |||||

| Operation | performed | sation | testing | performed | testing | sation |

| Beeshoek | 1 120 | 3 | 3 | 1 324 | 1 | 1 |

| Khumani | 7 701 | 1 | 1 | 6 145 | 1 | 1 |

| Black Rock | 3 678 | 3 | – | 4 549 | 31 | 9 |

| Cato Ridge Works | 3 553 | 136 | – | 2 716 | 40 | 2 |

| Dwarsrivier | 2 092 | 2 | 2 | 2 155 | 4 | 2 |

| Machadodorp Works | 1 070 | – | – | 917 | – | – |

| RMDC | 311 | 4 | 3 | 472 | 3 | 3 |

| Zeerust | 131 | – | – | 108 | – | – |

| Wonderstone | 128 | 1 | – | 102 | – | – |

Any cases that were referred for follow up as a result of routine medical surveillance and were subsequently found to meet the criteria for compensation in terms of the occupational health legislation were referred to the relevant industry association (Rand Mutual for mining operations and the Compensation Commissioner for industrial facilities).

In the current year, a total of 145 cases from the Assmang operations were referred for audiometric diagnostic testing, of which six were submitted for compensation. Over the same period, five cases from the AMT operations were referred for audiometric diagnostic testing, of which three were submitted for compensation.

Stakeholder engagement

The Assore group interacts with a wide range of internal and external stakeholders groups in the pursuit of its business. Each group of, often site-specific, stakeholders has different needs in terms of type of information required as well as mode and frequency of interaction, and the group’s approach to stakeholder engagement has been tailored accordingly, as summarised in the following table:

| Stakeholder | ||

| group | Responsibility | Mode of engagement |

| Investors | Dealing properly with all stakeholders in order to serve the best interests of shareholders on a sustainable basis. Commitment to full compliance with all relevant laws and rules, good corporate governance, transparency and fair dealing | Annual and six-monthly reports, SENS announcements, press statements |

| Employees and their representatives | Employing the most appropriately skilled individuals and investing in their development in a nondiscriminatory environment | Staff meetings at all levels, ‘toolbox talks’, inductions, health and safety meetings, internal publications, notice boards, union negotiations, career path planning |

| Joint-venture partners | Seeking mutually beneficial long-term relationships with joint-venture partners and industry peers | Representation on the Assmang Board and Excom and board meetings for individual Assore operations, active participation in industry associations |

| Contractors and suppliers | Seeking mutually beneficial long-term relationships with contractors and suppliers based on fair and ethical practices | Contract negotiations, tender processes, safety inductions, health and safety meetings, site inspections and audits, performance reviews, ISO certification |

| Customers | Establishing and maintaining mutually beneficial long-term relationships with customers based on fair and ethical practices | Customer site visits, contract negotiations, quality management system, conference attendance. Use of customer feedback to influence annual report content |

| Government | Observing the laws of the countries in which the Group operates | Statutory reporting, inspections by government representatives, permit applications, public participation process for Environmental Impact Assessments, engagement on targeted issues |

| Host communities | Promoting strong relationships with, and raising the capacity of, the communities in which the Group’s activities are located | Public meetings, public participation process for Environmental Impact Assessments, participation in Local Economic Development initiatives, funding of Corporate Social Responsibility initiatives |

| Non-governmental organisations | Development and maintenance of constructive relationships with relevant non-governmental organisations | Engagement on targeted issues and partnership on certain projects |

Materials stewardship

Leadership roles within the industry

Assore encourages its employees to assume leadership roles

in industry associations which aim to promote the use and

development of commodities which it produces, and to foster

cooperation between companies in these industry sectors to

address sustainability issues of common concern. Ore & Metal

is responsible for marketing the products produced by the

Assmang and the AMT operations. Ore & Metal recognises its

responsibility in promoting the sustainability of the business

by taking an active role in shaping the development and

performance of the sectors in which it operates.

In this regard, an Ore & Metal representative currently serves on the Occupational Health, Environment and Safety (OHES) Committee of the International Manganese Institute (IMnI). During the past financial year, IMnI has been particularly active in its sustainability initiatives, including the development of a “first pass” life-cycle assessment for manganese, which has been used for benchmarking purposes, as well as research into occupational hygiene monitoring for monitoring inhalable and respirable manganese. Ore & Metal also chairs the IMnI’s newly constituted Regulatory Committee, on which it also represents the interests of the South African manganese industry.

Ore & Metal continues to serve on the Executive Committee of the International Chrome Development Association (ICDA). During the current financial year, the chrome operations participated in ICDA’s Safety First reporting initiative, which provides member companies with the ability to benchmark its safety performance against its peers.

During the year under review, both the IMnI and ICDA have made a concerted effort to attract new members from emerging markets in order to improve sustainability performance, not only among its member companies, but across the industry sector.

Product registration and stewardship

Regulation EC1907/2006 of the European Parliament (generally

referred to within the industry as REACH) requires the evaluation,

authorisation and registration of chemical substances in order

to ensure their safe use. The group was part of the consortia

registering four substances in which it trades (iron, manganese, manganese dust

produced by CRA and chrome) and successfully

met the 30 November 2010 deadline for REACH registration.

The group’s Safety Data Sheets (which were revised in the previous financial year) are currently undergoing review to ensure compliance with the requirements of the Global Harmonised System of Classification and Labelling of Chemical (GHS), which has been implemented through South African National Standard SANS 10234:2008.

During the year, the group has initiated proactive engagement with its customers and suppliers in respect of its sustainability performance. In particular, as a result of calculating the group’s CCF, Ore & Metal has been able to provide customers with meaningful information on the carbon footprint of the products marketed.

Local economic development and corporate social investment

Social and Labour Plans (SLPs) have been developed for all group mining operations and submitted to the DMR in support of applications for the conversion of old order to new order mining rights. These SLPs detail a range of local economic development (LED) and corporate social responsibility (CSR) initiatives to which the Assore group has committed in order to facilitate economic diversification and social upliftment in our host communities.

Local economic development

LED projects have been established at all group operations and

have been selected to achieve sustainable job creation and

poverty alleviation in the communities that surround the group’s

operations. These projects are intended to develop and diversify

the economy of our host communities and to develop economic

opportunities that will endure beyond the end of mine life.

The group actively seeks to integrate LED projects with environmental management, particularly with respect to developing LED projects that have synergies with waste management and closure planning which generate economic opportunity as well as the financial provision required for mine closure. In this regard, a number of initiatives are underway to seek opportunities to convert mine wastes from being an economic liability into an economic asset.

The Cato Ridge Works has undertaken a risk-based assessment of the re-use of slag. This will be used to motivate to the Department of Water and Environmental Affairs that the reuse of manganese slag be listed as an activity not requiring a Waste License in terms of section 9 of the imminent Waste Classification and Management Regulations. This will develop a bigger market for slag sales in sectors such as the road construction industry and cement making industry, and a resultant further reduction in the amount of slag disposed of on site. Similarly, at Dwarsrivier, where waste rock is being used to produce aggregate, it is planned that the rate of aggregate production will increase to support the mine’s programme of local enterprise development.

Corporate social responsibility

Assore’s approach to CSR continues to place emphasis on

enhancing education, healthcare, safety and food security for

the communities in which the group operates.

During the reporting year, the Sacco Community Centre was commissioned at Black Rock. This is a 660 m2 facility that provides a range of recreational and social services to both the Black Rock village and surrounding communities. The complex includes a toddler care centre, a gym and a range of indoor recreational facilities including a cinema, a ten-pin bowling alley, board game lounges, table tennis, a model car racing track, a computer centre and an internet café. The project was constructed and equipped at a cost of R4 million.

AMT continues to support and extend the facilities at the Makgophe School on the RMDC mine property. In order to promote early childhood development and enhance school readiness, a crèche was established at Makgophe during the reporting year and the mine employs a teacher for Grade R. Other notable developments include the equipping of a computer centre with 34 computers and educational software in order to develop numeracy, literacy and computer skills, as well as upgrading of sporting facilities. The mine has also funded the award of bursaries for Dux learners which cover their school fees as well as the cost of uniforms and learning materials.

During the past year, Wonderstone has funded the establishment of the Rainbow Day Care facility in Letsopha township at a cost of R1,4 million. This includes purchase of furnishings and teaching materials, as well as installation of a borehole to ensure continuity of water supply to the facility.

Over the current year, the Assmang operations have focused the majority of their CSI expenditure on educational initiatives that benefit the neighbouring communities. A wide range of projects have been undertaken to support local schools, which include the construction of new classrooms, the renovation and maintenance of existing infrastructure, funding of teaching materials and the provision of salary subsidies for teachers.

As part of the group’s ongoing commitment to developing the potential of its staff and generating sustainable livelihoods, the group continues to provide a range of bursaries and other study support to enable employees and their families to purse a variety of technical and vocational qualifications.