SUSTAINABILITY REPORT

This report provides a brief summary of health,

safety and environmental performance across

the operations of the Assore group. Assore also

recognises that it has a responsibility to promote

the sustainability of its business by taking an active

role in shaping the development and performance

of the sectors in which it operates.

This sustainability report covers all of the entities in which the Assore group has an interest (other than investments) and, for ease of reference, has been szlit into the following two sections: |

|||||||||||||

| • | Assmang, jointly controlled by Assore 50% and ARM (African Rainbow Minerals Limited) 50%, which includes the following operations: | ||||||||||||

|

|||||||||||||

| • | Subsidiary companies of Assore (referred to as the AMT operations), which include: | ||||||||||||

|

|||||||||||||

The 2010 financial year saw implementation of significant changes to site environmental, health and safety management systems to ensure compliance with recent legislative changes relating to waste management, environmental impact assessments and permitting. Against the changing legislative background, Assore continued to strengthen its management systems, integrating these more closely with corporate risk management structures and processes. As a result, sustainability-related risks now feature more prominently in the corporate risk register, leading to earlier identification and management of such risks.

MANAGEMENT SYSTEMS

The group’s sustainability risk management systems are based on the International Standards Organisation (ISO) suite of standards.

All group operations (with the exception of Khumani and Zeerust) are certified to the ISO 9001:2008 quality standard and the ISO 14001:2004 environmental standard, with RMDC having gained certification to ISO 14001 in October 2010 after the end of the reporting period. It is intended that Khumani will be certified to these standards during the 2011 financial year, and similar certification will be sought by Zeerust once the open-cast mining operation is under way.

Certification to the internationally recognised OHSAS 18000 occupational health and safety management standard has been achieved at the majority of Assmang’s operations, and it is planned that the two remaining mines (Khumani and Black Rock) will be certified to this standard in the next financial year.

To standardise sustainability risk management systems across the Assmang operations, a series of corporate safety, health and environmental standards were rolled out across the group during the reporting year. Over the same period, the AMT operations revised their health and safety, environmental and quality policies and introduced groupwide guidelines for the monitoring and reporting of sustainability performance.

In addition to strengthening the sustainability management systems, specific initiatives are being driven from a corporate level seeking, inter alia, to develop corporate standards on water monitoring and data collection and creating more robust baseline information in areas such as energy management, greenhouse gas emissions, waste generation and water usage. Using such information the group plans to identify and drive water and energy-efficiency projects over the next few years.

APPROACH TO REPORTING

Quarterly reports on compliance with safety, health and environmental legislation for all Assore operations are submitted to the Audit and Risk Committee for review. Similarly, a review of safety, health and environmental performance takes place quarterly within Assmang and is attended by divisional executives and corporate personnel as well as senior operational staff.

Assore is reporting for the first time on environmental, health and safety performance in accordance with Global Reporting Initiative (GRI) G3 indicators (refer page). In line with good practice, an initial suite of indicators has been selected on the basis of their materiality to the specific risk profile of the operations and are discussed in the sections below. Assore will continue to strengthen its reporting capabilities in line with the requirements of the standards of its management systems as well as those of the JSE Limited (JSE), including the requirements of the King III Code of Governance Principles for South Africa (King III).

This is the first year that a number of the sustainability data sets presented in this report have been gathered in a comparable manner by all group sites. It is intended that data generated by the ongoing monitoring programmes that have been initiated over the past year will yield comparative data sets that can be reported on in subsequent annual reports to demonstrate performance year on year.

LEGAL COMPLIANCE

During this financial year, Assmang’s Black Rock operation paid an administrative fine of R161 000 in terms of section 24G of the National Environmental Management Act for commencing a housing development without the necessary environmental authorisation. No fines or prosecutions were incurred by the AMT operations over the reporting period under consideration.

During the reporting year, a total of 16 section 54 notices were issued to Assmang operations in terms of the Minerals and Petroleum Resources Development Act (MPRDA): 6 at Beeshoek, 7 at Black Rock and 3 at Dwarsrivier. No section 54 notices were issued for the AMT operations.

Safety, health and environment (SHE) assurance audits were conducted at RMDC, Zeerust, Wonderstone and head office operations by Environmental Resource Management (ERM) during the last quarter of the current financial year to assess legal compliance. These audits highlighted no material issues, but did identify opportunities for improvement which are currently being actioned. To date these assurance audits have taken place every two years, but in light of significant changes to the mines’ risk profiles due to the major developments currently under way at RMDC and Zeerust, consideration is being given to conducting these audits more frequently.

Corporate audits (using external specialists in the legal and operational fields of safety, health and environmental management) are performed for Assmang operations every second year. The previous audit, performed in the 2008 financial year, focused on environmental management and legal compliance on both a corporate and an operational level. The next round of audits will be performed in the next financial year and will address both legal compliance and performance against the corporate standards which have been introduced since the previous audit.

ENERGY

Prudent management of energy use is a key focus area for both Assore and Assmang, since energy utilisation has a significant impact on the group’s operational and financial efficiency. Increased energy efficiency will also yield an environmental benefit by contributing to a reduction in greenhouse gas (GHG) emissions.

Assmang is the major consumer of electricity in the group because of its two smelter operations at Cato Ridge Works and Machadodorp Works. Assmang is an active member of the Energy Intensive Users Group and has developed an Energy-efficiency Charter which is aimed at the development and implementation of energyefficient practices for the organisation.

Electricity and diesel consumption

The table below reflects year-on-year changes in consumption of the two major energy sources on the AMT and Assmang operations, namely diesel and electricity.

The group is actively exploring various energyefficiency initiatives and diesel generators have been installed at all underground mining operations in order to supply uninterrupted power to ensure employee safety during power outages.

Greenhouse gas emissions

In order to establish a baseline for group operations’ energy usage and GHG emissions, a corporate carbon footprint was developed for the previous financial year (the most recent period for which a complete data set was available). This study was undertaken to:

• quantify the Group’s greenhouse gas emissions;

• establish an energy use baseline which can be used to identify opportunities for future energy savings and energy efficiency;

• identify further monitoring required to monitor energy consumption by specific activities and facilities on the sites; and

• benchmark GHG emissions per tonne of product produced.

This baseline will serve not only as a tool for evaluating and optimising energy input costs but also represents a further step towards responsible product stewardship beyond mere legal compliance. The benchmarking data generated by this study will provide stakeholders with data on the carbon footprint of our products, thus demonstrating the group’s responsiveness to our clients’ requests for more detailed disclosure on this issue.

Diesel use |

Diesel use |

Electricity use |

Electricity use |

|

FY2010 |

FY2009 |

FY2010 |

FY2009 |

|

| Operation | (’000 ℓ) |

(’000 ℓ) |

(MWh) |

(MWh) |

| Beeshoek | 1 604 |

9 924 |

33 529 |

42 709 |

| Khumani | 18 844 |

14 000 |

87 720 |

72 386 |

| Black Rock | 3 094 |

4 047 |

87 609 |

84 999 |

| Cato Ridge Works | 542 |

463 |

533 183 |

505 950 |

| Dwarsrivier | 1 183 |

1 345 |

26 750 |

23 897 |

| Machadodorp Works | 417 |

417 |

645 107 |

840 000 |

| RMDC | 1 673 |

2 730 |

4 378 |

4 123 |

| Zeerust | 77 |

104 |

423 |

200 |

| Wonderstone | 151 |

182 |

2 025 |

1 184 |

The carbon footprint has been determined in accordance with the GHG Protocol Corporate Accounting and Reporting Standard and will be reported on in next year’s annual report.

Initial findings of this study indicate that electricity consumption is the major contributor to Assmang’s corporate carbon footprint and reflects energy sourced from Eskom grid supply, particularly by the Cato Ridge Works and Machadodorp Works smelters. Other major contributors to the Assmang carbon footprint are reductants used in the smelting process and rail transport of products.

Diesel usage is the major contributor to Assore’s corporate carbon footprint (reflecting fuel consumption by the mining fleets), with the next largest contribution to the carbon footprint coming from electricity consumption.

WATER

Virtually all of the group’s mines are located in water-scarce regions, so the prudent management of water usage and the prevention of water pollution are key objectives at all our operations. Water usage is reported on by all operations in their monthly management report, and is summarised in the table below. Water quality and groundwater level monitoring is undertaken on the sites according to corporate environmental monitoring standards.

During the reporting period, water balances have been updated for most of the group’s operations with the intention of ensuring compliance with pollution control legislation and optimising use of the water resource to ensure continuity of water supply. As an outcome of these studies, significant resources have been allocated for the upgrading of pollution control dams and water treatment facilities on the sites. The investigations have also highlighted the requirement for more detailed monitoring of water consumption by individual facilities and processes on the sites in order to assist in achieving optimal use of the water resource.

WASTE

Mining and smelting operations produce a range of waste streams that require specialist disposal. Volumetrically, the most significant waste streams are tailings and waste rock at the mining operations, and slag from the smelters, as summarised in the table overleaf.

Integrated tailings management strategies are being developed at RMDC and Zeerust operations to provide sufficient capacity to dispose of the larger tailings volumes that will be generated as a result of extended mine life and increased production rates. These management strategies will focus on developing tailings disposal facilities that:

| • | allow tailings disposal in a manner that is legal and not detrimental to the environment; |

| • | maximise the recovery of water from tailings which can be recirculated for reuse in the process (thus reducing water consumption); and |

| • | provide the opportunity for safe and costefficient tailings reclamation and reprocessing in the future, in order to optimise utilisation of the mineral resource. |

Studies are also under way at the group’s smelters and at the Wonderstone operation to identify potential uses for slag and waste rock respectively, thus reducing the volume of mineral waste to be disposed of on the sites.

| Water consumption (m3) | ||

Water consumption |

Water consumption |

|

FY2010 |

FY2009 |

|

| Operation | (m3) |

(m3) |

| Beeshoek# | 5 426 839 |

7 028 000 |

| Khumani | 2 432 733 |

1 464 443 |

| Black Rock | 883 707 |

694 446 |

| Cato Ridge Works | 329 713 |

369 714 |

| Dwarsrivier | 73 638 |

479 820 |

| Machadodorp Works | 52 031 |

147 763 |

| RMDC | 173 485 |

116 703 |

| Zeerust* | Not available |

Not available |

| Wonderstone | 4 378 |

5 836 |

# Water consumption statistics for Beeshoek include water for the local community which is taken from the Gomagara pipeline

LAND MANAGEMENT AND MINE CLOSURE

Land disturbanceMining and minerals processing causes the disturbance of significant areas of land, principally as a result of mining activity and waste disposal. Each operation has a legal requirement to rehabilitate the disturbed areas and return this land to a land use that does not pose a safety risk and does not have a detrimental effect on the health and sustainability of ecosystems or neighbouring communities. The areas of land disturbed by group operations are detailed in the table below.

Where possible, concurrent rehabilitation is undertaken on the sites to rehabilitate areas where activities relating to mining and mineral processing have been completed.

In order to assist in upgrading existing land management practices and the selection of sustainable post-closure land uses, Assore has undertaken to develop biodiversity action plans (BAPs) for its operations. During the reporting years, BAPs were commissioned for the Black Rock, Dwarsrivier, RMDC and Zeerust operations, and a biodiversity study is planned for Machadodorp during the coming financial year.

Closure planning and financial provisions for rehabilitation

Closure plans developed for the group operations inform the financial provision made for rehabilitation and closure, which is achieved through a combination of contributions to an environmental trust fund and financial guarantees. Many of the group’s current closure plans are currently under revision to take account of mine expansion projects and other changes to operations. These revised closure plans will form the basis for review of the existing site closure provisions (which are detailed in the table overleaf) during the next financial year.

| Waste generated by operations (tons) | ||

Waste rock/slag |

Tailings/slag |

|

| Operation | (m3) |

(tons) |

| Beeshoek* | - |

1 120 340 |

| Khumani | 15 423 509 |

1 310 810 |

| Black Rock | 135 541 |

352 376 |

| Cato Ridge Works | Not applicable |

252 227 |

| Dwarsrivier | 587 733 |

134 945 |

| Machadodorp Works | Not applicable |

78 304 |

| RMDC | 1 381 860 |

57 853 |

| Zeerust* | Not applicable |

41 177 |

| Wonderstone | 130 529 |

Not applicable |

stock piles. Zeerust produced no waste rock during the year, as product was exclusively based on tailings processing

| Land disturbance (ha) | ||

| Operation | Area currently disturbed (ha) |

|

| Beeshoek | 850 |

|

| Khumani | 700 |

|

| Black Rock | 1 441 |

|

| Cato Ridge Works | 93 |

|

| Dwarsrivier | 144 |

|

| Machadodorp Works | 976 |

|

| RMDC | 202 |

|

| Zeerust | 24 |

|

| Wonderstone | 41 |

|

| Financial provision for closure at 30 June 2010 | |||

Environ- |

Current |

||

Total |

mental |

guarantees |

|

liability |

fund |

in place |

|

| Operation | (R’000) |

(R’000) |

(R’000) |

| Beeshoek | 87 005 |

51 524 |

- |

| Khumani | 106 932 |

11 099 |

38 000 |

| Black Rock | 85 704 |

22 232 |

20 065 |

| Dwarsrivier | 27 289 |

8 034 |

9 267 |

| RMDC | 12 411 |

6 695 |

6 866 |

| Zeerust | 1 601 |

2 222 |

40 |

| Wonderstone | 3 768 |

2 566 |

5 657 |

| Total | 324 710 |

104 371 |

79 895 |

Cato Ridge Works and Machadodorp Works are classified as industrial (rather than mining) facilities and there is therefore no legal requirement to make financial provision for closure or rehabilitation of these operations.

HUMAN RESOURCES

Due to the suspension of operations at Xertech, Assore regrettably had to retrench 30 workers in February 2010, 11 of whom were afforded alternative employment in other group companies (refer page).

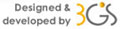

The group undertakes statutory reporting on employment equity and other labour-related issues to both the Department of Labour and the Department of Mineral Resources. The occupational levels and employment equity categories reported on are based on the definitions outlined in the Employment Equity Act and the Broad-based Socio-economic Empowerment Charter for the Mining Industry (the Mining Charter) and are summarised below.

It should be noted that while the employment equity targets set in the Mining Charter do not apply to the group’s smelters, employment equity statistics are presented for the Cato Ridge Works and the Machadodorp Works operations for the sake of complete and consistent reporting.

| Contractors | |||

Contractors as a |

|||

Permanent |

Temporary/contract |

proportion of the |

|

| Operation | employees |

employees |

total workforce (%) |

| Beeshoek | 277 |

7 |

2,5 |

| Khumani | 909 |

5 164 |

85,0 |

| Black Rock | 1 358 |

1 283 |

52,1 |

| Cato Ridge Works | 607 |

74 |

10,9 |

| Dwarsrivier | 1 129 |

706 |

38,5 |

| Machadodorp Works | 612 |

234 |

27,7 |

| RMDC | 167 |

278 |

62,5 |

| Zeerust | 14 |

31 |

68,9 |

| Wonderstone | 116 |

30 |

20,6 |

| Total | 5 189 |

7 807 |

60,0 |

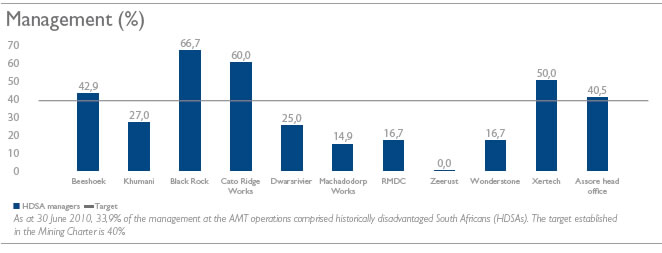

As at the end of the financial year, the percentage of women in mining in the Assmang operations was 13,0%, while the combined percentage in the AMT operations and Assore head office amounted to 16,5%. These statistics compare favourably with the target of 10% of women in mining, specified in the Mining Charter, and the respective operations’ achievements against this target are summarised above.

Contractors

In addition to the permanent workforce, the group employs a significant number of contractors to perform a variety of tasks, ranging from construction to contract mining, minerals processing and security. A breakdown of the operational workforce as at 30 June 2010 on the basis of employment contract is detailed in the table on the previous page.

The percentage of contractors as a proportion of the workforce is currently higher than in previous years due to major expansion projects that are being undertaken at a number of the group’s operations. The contractors mainly comprise construction workers who are involved with the Khumani Expansion Project as well as the underground developments at RMDC and preparations for the commencement of open-cast mining at Zeerust.

Labour relations

No strikes and lockouts exceeding a week were experienced by any Assmang or the AMT operations during the reporting year.

Safety

One of the group’s core values is ensuring that our operations are managed in a manner that safeguards the safety and health of our employees.

To this end, our existing management systems are continuously evolving to address the changing risk profiles of our operations, and we consistently strive to improve our safety performance so that workplace injuries and occupational diseases are minimised.

Once again there were no fatalities on any of the AMT operations during the reporting year. However, one fatal accident occurred during the year at Assmang’s Machadodorp Works. On 10 April 2010, Mr Erick Maluka was severely injured while at work, and later passed away in hospital.

The inquiry convened by the Department of Labour into the furnace 6 explosion that took place at the Cato Ridge Works on 24 February 2008, continued with its hearings during the course of the reporting period. The last hearings in the reporting period took place during May 2010. The proceedings were not completed by the end of the reporting period, however, and were adjourned to November 2010. Since the inquiry proceedings have not yet been completed, Assmang is not in a position to comment further on the matter.

Lost-time injury (LTI) statistics and lost-time injury frequency rates (LTIFR) for each of the operations for the financial year are presented in the table below. The LTIFR is calculated on the basis of 200 000 hours.

OCCUPATIONAL HEALTH AND HYGIENE MONITORING

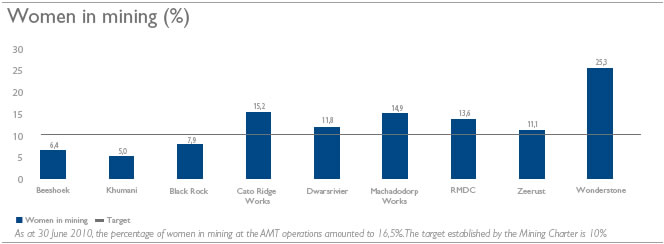

The group recognises that proactive management of the occupational health of our workforce is central to ensuring the sustainability of our business. In order to ensure that the specific occupational health risks associated with each of our operations are effectively managed, specialist occupational health service providers are engaged by each of the operations to implement medical surveillance programmes in accordance with legal requirements.

During the reporting year, Assmang introduced a number of group standards for occupational health management. In order to monitor the effective implementation of these standards, an external occupational nurse was engaged to assist in standardising occupational health management across the organisation and to perform quarterly audits against group standards.

In view of the significant number of new employees hired at RMDC and Zeerust during the reporting year, particular priority was placed on ensuring that entry medical examinations meet the statutory requirements. In view of the suspension of operations at Xertech, emphasis was placed on closing out potential occupational health concerns identified during the annual medical examinations conducted in December 2009 and all recommended follow-up procedures from these examinations have since been completed.

The number of employees who underwent occupational health screening (including the number of cases referred for follow-up and compensation) during the reporting year is summarised below.

Any cases that were referred for follow-up as a result of routine medical surveillance and subsequently found to meet the criteria for compensation in terms of the occupational health legislation were referred to the relevant industry association (Rand Mutual Assurance for mining operations and the Compensation Commissioner for industrial facilities).

LTI |

LTI |

LTIFR |

LTIFR |

|

| Operation | 2010 |

2009 |

2010 |

2009 |

| Beeshoek | 1 |

1 |

0,88 |

0,54 |

| Khumani | 9 |

5 |

1,42 |

2,25 |

| Black Rock | 12 |

14 |

2,62 |

3,3 |

| Cato Ridge Works | 10 |

8 |

4,86 |

3,29 |

| Dwarsrivier | 23 |

13 |

9,78 |

5,01 |

| Machadodorp Works | 5 |

10 |

2,40 |

4,62 |

| RMDC | 6 |

4 |

1,86 |

5,96 |

| Zeerust | 1 |

0 |

2,87 |

0,0 |

| Wonderstone | 3 |

4 |

2,45 |

17,16 |

| Assore head office | 1 |

0 |

4,73 |

0,00 |

| Assmang head office | 0 |

0 |

0 |

0 |

The hearings of the Department of Labour inquiry, into the alleged cases of manganism at the Cato Ridge Works, were completed during late 2008. After the end of the reporting period, during July 2010, Assmang was informed that the Department had completed its report on the proceedings. This report has not yet been made available to the company. On a related matter, the arbitration proceedings on the claims of unfair dismissal by the former employees who had been initially diagnosed with manganism, were concluded. On 1 September 2010, after the end of the reporting period, the arbitrator found that the dismissals of the former employees had not been unfair, and the applications of the former employees for reinstatement were dismissed.

STAKEHOLDER ENGAGEMENT

Assore interacts with a wide range of internal and external stakeholder groups in the pursuit of its business. Each group of stakeholders has different needs in terms of type of information required as well as mode and frequency of interaction, and the group’s approach to stakeholder engagement has been tailored accordingly, as summarised in the following table:

Stakeholder group |

Responsibility |

How we engage |

| Investors | Dealing properly with all stakeholders | Annual and six-monthly reports, SENS |

| in order to serve the best interests of | announcements, press statements | |

| shareholders on a sustainable basis. | ||

| Commitment to full compliance with all | ||

| relevant laws and rules, good corporate | ||

| governance, transparency and fair | ||

| dealing | ||

| Employees | Employing the most appropriately | “Toolbox talks”, inductions, health and |

| and their | skilled individuals and investing in their | safety meetings, internal publications, |

| representatives | development in a non-discriminatory | notice boards, union negotiations, career |

| environment | path planning | |

| Business partners | Seeking mutually beneficial long-term | Representation on the Assmang board |

| relationships with joint-venture partners | and Excom, board meetings for individual | |

| and industry peers | Assore operations, active participation in | |

| industry associations | ||

| Contractors and | Seeking mutually beneficial long-term | Contract negotiations, tender processes, |

| suppliers | relationships with contractors and | safety inductions, health and safety |

| suppliers based on fair and ethical | meetings, site inspections and audits, | |

| practices | performance reviews | |

| Customers | Establishing and maintaining mutually | Customer site visits, contract negotiations, |

| beneficial long-term relationships with | quality management system, conference | |

| customers based on fair and ethical | attendance | |

| practices | ||

| Government | Observing the laws of the countries in | Statutory reporting, inspections by |

| which the group operates | government representatives, permit | |

| applications, public participation process | ||

| for environmental impact assessments, | ||

| engagement on targeted issues | ||

| Host communities | Promoting strong relationships with, and | Public meetings, public participation |

| raising the capacity of the communities | process for environmental impact | |

| in which the group’s activities are | assessments, participation in local | |

| located | economic development initiatives, funding | |

| of corporate social responsibility initiatives | ||

| Non- | Development and maintenance of | Engagement in targeted issues |

| governmental | constructive relationships with relevant | |

| organisations | non-governmental organisations |

MATERIALS STEWARDSHIP

Ore & Metal Company Limited is responsible for marketing the products produced by Assmang and the AMT operations and recognises its responsibility to promote the sustainability of its business by taking an active role in shaping the development and performance of the sectors in which it operates. Assore therefore encourages its employees to assume leadership roles in industry associations which aim to promote the use and development of commodities which it produces and to encourage cooperation between companies in these industry sectors to address issues of common concern.

In this regard, Mr Alastair Stalker currently serves as Chair of the Executive Committee of the International Manganese Institute (IMnI) that represents manganese ore and alloy producers, manufacturers of manganese-based products, traders, industry service providers and companies using manganese to manufacture their products. Mr Alistair McAdam continues to serve on the Executive Committee of the International Chrome Development Association, which serves a similar function for the chrome industry.

Regulation EC 1907/2006 of the European Parliament (generally referred to within the industry as REACH) requires the evaluation, authorisation and registration of chemical substances in order to ensure their safe use. The aim of REACH is to improve the protection of human health and the environment through the better and earlier identification of the intrinsic properties of chemical substances.

The new law came into force on 1 June 2007 and substances must be registered in a central database run by the European Chemicals Agency by 30 November 2010. Assmang is part of the consortia registering four substances in which it trades: iron, manganese, manganese dust produced by CRA and chrome.

During the reporting year, the materials safety data sheets (MSDSs) for the products produced by both the AMT and Assmang operations were reviewed and comprehensively revised by an external occupational health and safety service provider. This revision has been undertaken to restructure MSDSs into the standard 16-point format and to ensure compatibility with the requirements of the Global Harmonised System of Classification and Labelling of chemicals (GHS) and REACH initiatives. This review was also prompted by customer requests to seek responsible guidance on the management of occupational health and safety risks for our customers and transport agents, as well as our own employees. Such pressures form part of a changing operational climate in which legal compliance within our own jurisdiction is regarded as a minimum, and producers such as Assore are increasingly having to assume responsibility for our product beyond our jurisdiction.

CORPORATE SOCIAL INVESTMENT AND LOCAL ECONOMIC DEVELOPMENT

Social and Labour Plans (SLPs) have been developed for all Group mining operations and submitted to the former Department of Minerals and Energy in support of applications for the conversion of old-order to new-order mineral rights. These SLPs detail a range of local economic development (LED) and corporate social responsibility (CSR) initiatives to which Assore has committed in order to facilitate economic diversification and social upliftment in our host communities.

Local economic development

LED projects have been established at all group operations and have been selected to achieve poverty alleviation and job creation. These projects are intended to develop and diversify the economy of our host communities and to develop sustainable economic opportunities that will endure beyond the end of mine life.

LED projects undertaken by Assmang operations include establishment of the Gamagara integrated cleaning enterprise at Khumani, and development of bulk water supply infrastructure to seven villages in the vicinity of Black Rock.

A brickmaking project has been established at RMDC to manufacture bricks and paving stones for the local market which suffers from a shortage of affordable construction materials. During 2010, RMDC also developed a poultry breeding project in Makgophe village (the closest community to the mine) and finance has been provided to initiate a sewing project in Malorwe, another village located within close proximity of the mine.

Corporate social responsibility

Assore’s approach to corporate social responsibility (CSR) continues to place emphasis on enhancing education, healthcare, safety and food security for the communities in which we operate.

Beeshoek has contributed to community safety by funding the upgrade of the Postmasburg, Kimberley, Kathu and Beeshoek road crossings.

In terms of education, Dwarsrivier has established an early childhood development programme in six communities close to the mine.

Machadodorp Works has helped to upgrade healthcare in Emakhazeni local municipality through the development of a healthcare and trauma centre.

RMDC has continued to provide support to the Makgophe Primary School (whose classroom expansion was completed during the previous financial year) and funded the further development of the school through the addition of a crèche facility during the reporting year.

RMDC continues to enhance food security and nutrition in surrounding villages by providing ongoing support for a community vegetable garden. In the reporting year, RMDC has also financed the construction of a pavilion, restrooms, store room and kiosk at the sports pavilion which was developed as a community project in 2008.

During the reporting year, RMDC partnered with the Moses Kotane local municipality to provide wheelchairs, blankets, groceries and other consumables to the Malorwe Home-Based Care Centre which provides home-based care to people living with HIV/AIDS within communities close to the mine.

During the reporting year, the construction of the Driekuil Museum at Wonderstone was completed. This museum has been created in collaboration with the Natal Museum to preserve and display rock art found on the Driekuil koppie and display materials are currently being developed which will assist visitors in interpreting the exhibits.

As part of our ongoing commitment to developing the potential of our staff and generating sustainable livelihoods, the group continues to provide a range of bursaries and other study support to enable our employees and their families to pursue a variety of technical and vocational qualifications.